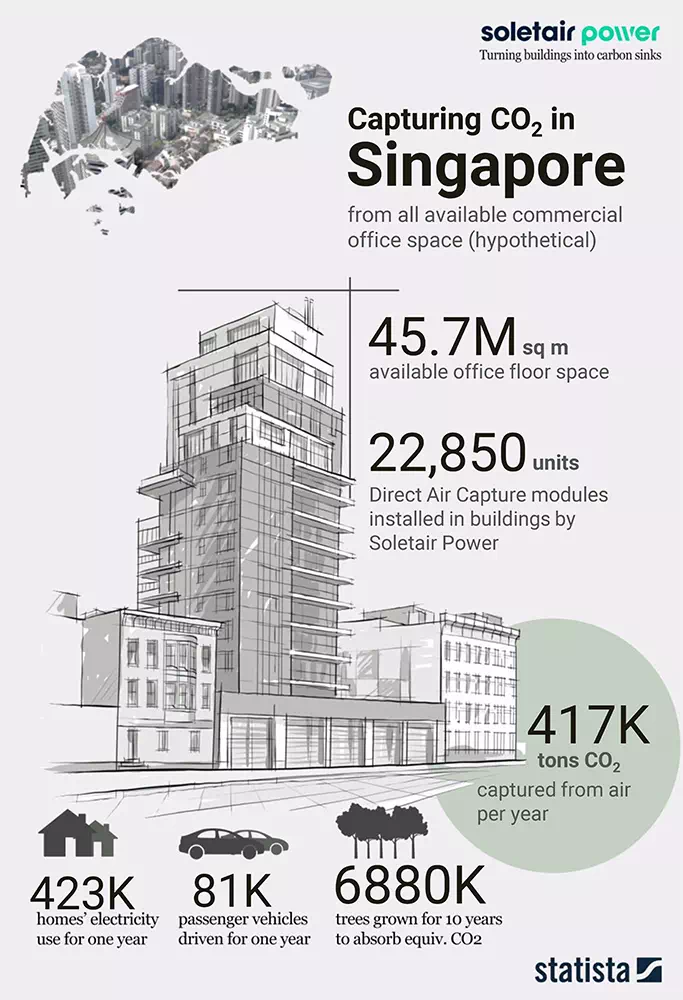

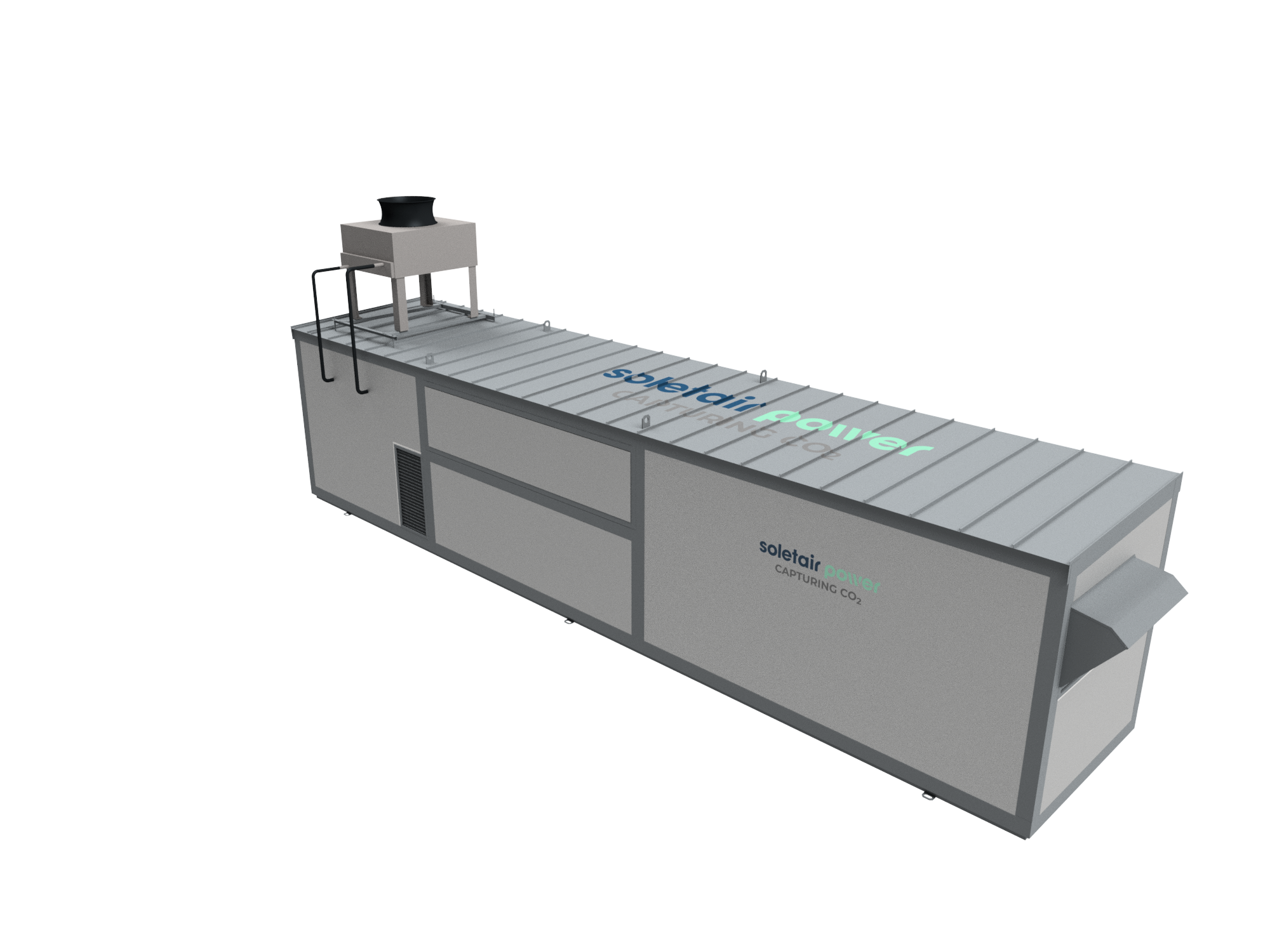

Soletair Power’s HVAC Integrated CO2 Capturing Unit is a modular carbon capture system that operates plug-and-play. Each unit can capture up to 20 tons of CO2 per year, equivalent to 3 hectares of Nordic forest aged 30 years, and can be integrated into the building’s HVAC (heating, ventilation, and air conditioning) system. More units can be added to increase the capture capacity. Installation of the system also lowers HVAC energy costs by controlling the building’s ventilation runtime based on CO2 levels. The unique selling points of the system are its building retrofitability, easy installation, modular design, weatherproof capture, and low water/ heat/ electricity/ material/ carbon footprint.

For a standard ventilation unit handling 3.3 m3/s, each Soletair Power Building-HVAC-Integrated CO2 Capture Unit can capture ~47 kilograms of carbon dioxide per 8-hour day or 20 tonnes per year. On average, there are about 20 modules per building.

So, each commercial building equipped with Soletair Power’s technology can capture up to 400 tonnes of carbon dioxide per year from the ambient air.

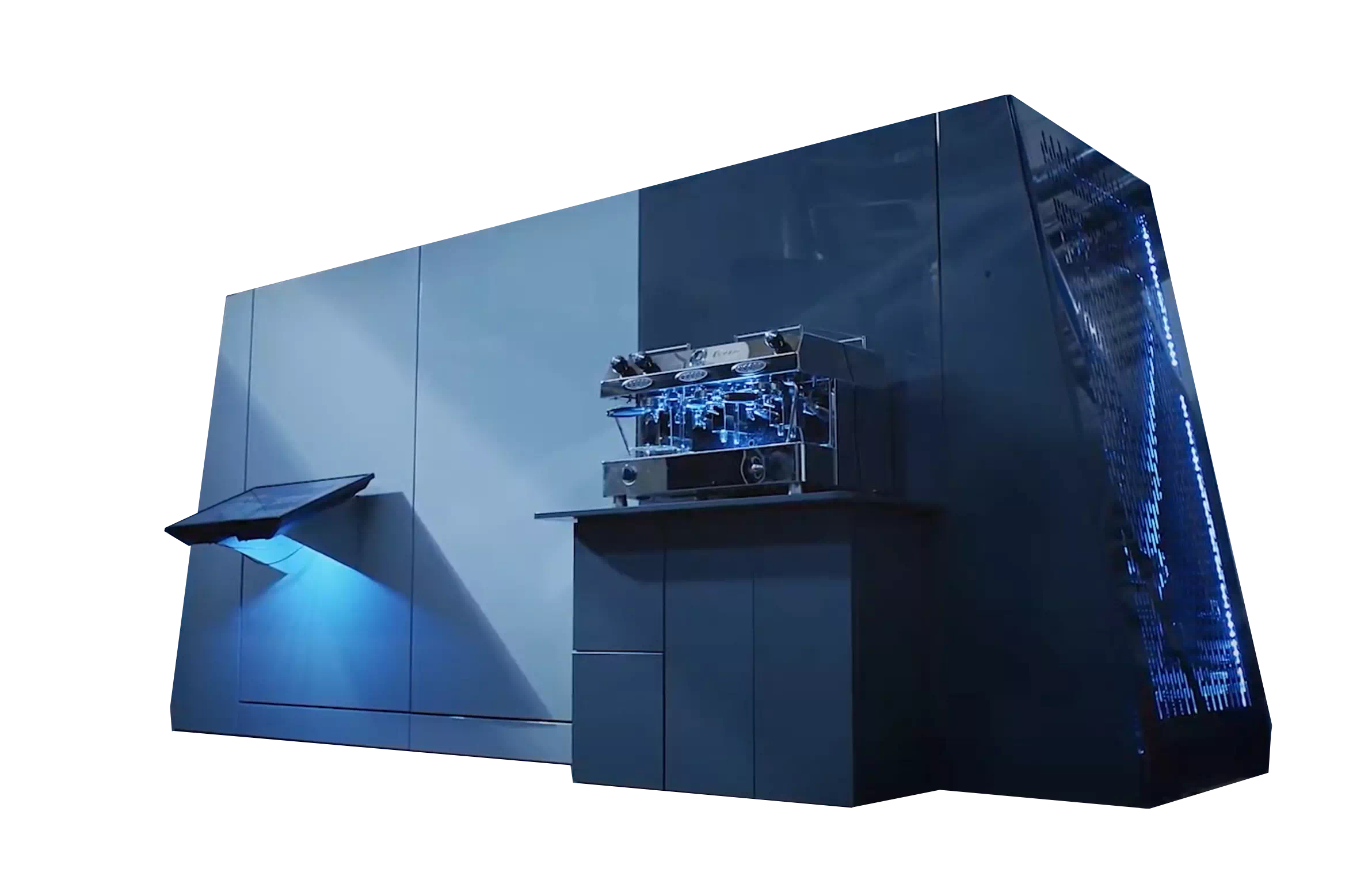

We have installed a system in Wärtsilä Sustainable Technology Hub, Vaasa, Finland, where they have a standard ventilation unit handling 3.3 m3 of air per second. Soletair Power’s CO2 capture system has a dimension of 3m x 3m x 3m (LWH). So, it is small in land usage since it can operate in buildings.

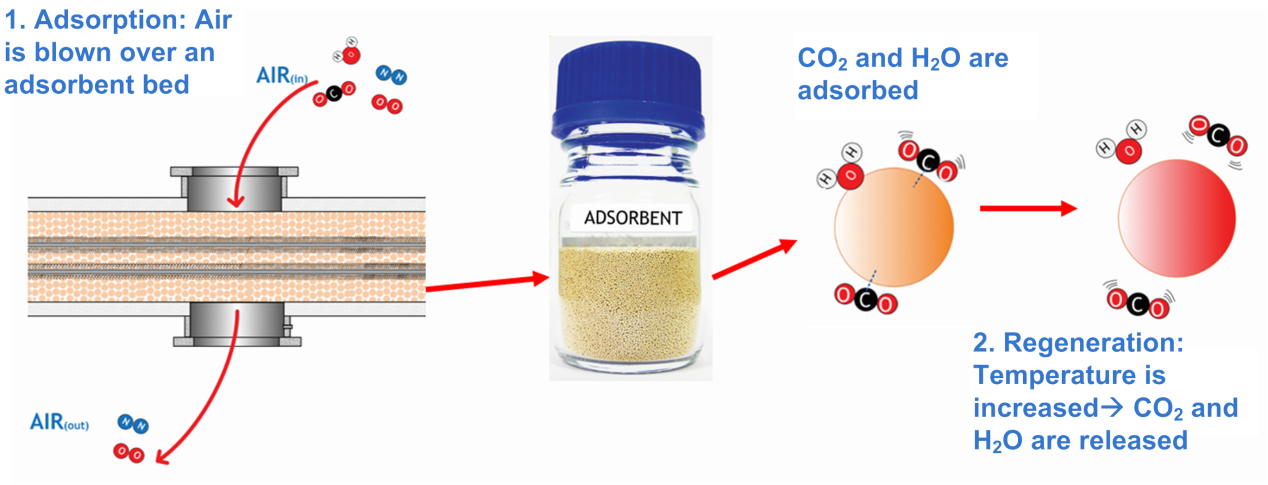

We are using the Temperature vacuum swing adsorption process in our direct air capture technology. We have our own proprietary Amine-functionalized solid sorbent. From the HVAC system, incoming air is pushed through these sorbent filters, and carbon dioxide is trapped (or adsorbed) by them. When the filter is saturated with these compounds the machine is closed and regenerated via vacuum and heating at 90°C to collect CO2. Moisture is condensed leaving pure CO2 for compression. The captured CO2 is stored in a separate storage container.

The system itself is fully automated. It can be connected to several IoT sensors and also to the building’s automation system. Signals to external systems can be pushed from our control cabinet and remote operation is possible. We can also monitor and control it remotely through the Internet.

Soletair Power’s direct air capture system is uniquely optimized for integration with urban infrastructures. Compared to most direct air capture technologies, Soletair Power’s system operates at almost zero noise level, making it ideal for installation in buildings.

Currently, existing customers are utilizing the CO2 themselves for their own R&D purposes. We can help customers have utilization cases with captured CO2 through our different CO2 utilization and storage partners. For example, in Dubai, we made the world’s first compact Power-to-X demonstration unit for our customers where we partnered with Q-Power and Wärtsilä.

We can provide CO2 utilization assistance with our partners; depending on the location of the facility.

Clean and environment-friendly process

Our proprietary sorbent is highly efficient and does not have any hazardous components.

Patented and proven technology

Soletair Power has patents applied and granted in many countries in APAC, US and EMEA region.

Competitive and cost-efficient technology

The technology retrofits with existing HVAC systems inside buildings, making the process cost-efficient.

Compatible with a variety of energy sources

Soletair Power Carbon Capture technology uses mainly electricity. Energy can be obtained from renewable or clean energy like solar and wind, thermal, district heating, heat pumps etc.

Almost no maintenance

There is almost no corrosion or damage; it is almost maintenance-free. The life span of the sorbent is above ten years.

Easy to scale up and applicable to various industries

Commercial buildings, shopping malls, mills, power plants, breweries refineries, farms etc.